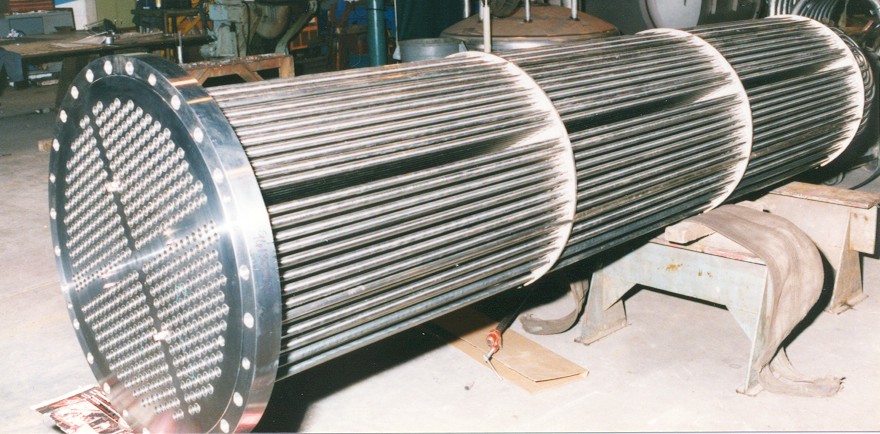

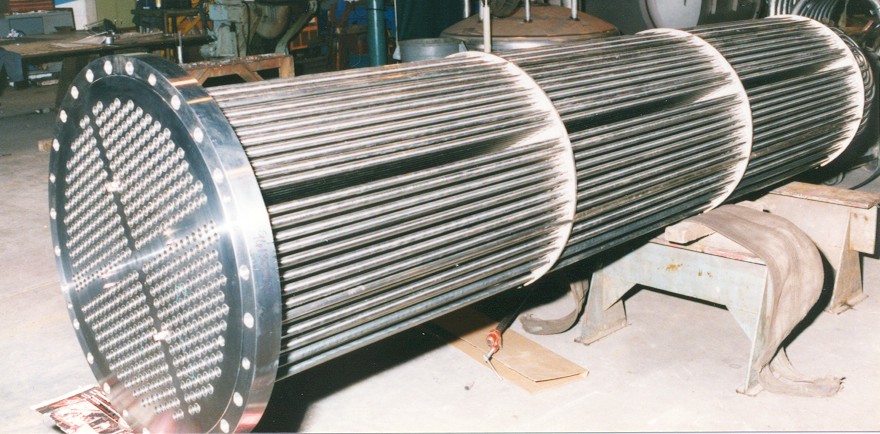

Design: Using state-of-the-art BJAC computer aided design sys tems, RAS determines precise thermal ratings and mechanical designs for an assortment of shell and tube heat exchangers. Our Q.C. Department is stringent on analyzing every detail during production, all heat exchangers meet the requirements of TEMA and can be designed to the ASME Section VIII Division 1 or Divison 2 Codes. Heat exchangers can be fabricated in all TEMA configurations, from single pass to multi-pass to "U" tube configurations, with or without removable bundles. Heads can be fabricated using traditional bonnets, or with channels to facilitate cleaning the tube side. Impingement protection is available to prevent wear of the tubes on inlet connections. Several types of supports are available such as: saddles for horizontal units and lugs for vertical units. tems, RAS determines precise thermal ratings and mechanical designs for an assortment of shell and tube heat exchangers. Our Q.C. Department is stringent on analyzing every detail during production, all heat exchangers meet the requirements of TEMA and can be designed to the ASME Section VIII Division 1 or Divison 2 Codes. Heat exchangers can be fabricated in all TEMA configurations, from single pass to multi-pass to "U" tube configurations, with or without removable bundles. Heads can be fabricated using traditional bonnets, or with channels to facilitate cleaning the tube side. Impingement protection is available to prevent wear of the tubes on inlet connections. Several types of supports are available such as: saddles for horizontal units and lugs for vertical units. RAS continuously seeks new and improved ways to help our customers be more productive. By offering a wide array of options, customers can consider many alternatives. Configuration: Tube sizes are available from 5/8" O.D. to 1-1/2" O.D.

Tube sheets are drilled, reamed, and double serrated according to specifications. Tube to tube sheet joints are roll expanded, obtaining proper tube wall reduction. Seal and strength welded joints are available through the TIG welding process. RAS is concerned with every aspect of a customers product. For example, when a mechanical design calls for an expansion joint, RAS has found that it is beneficial to use flanged or bellowed type expansion joints, due to the different thermal expanding properties from the tube side to the shell side. This prevents damage to the tube and tube sheet joints. If you would like us to quote a heat exchanger, please click the link below to open a form that can be printed. Complete the form and fax to 609-371-1200. Heat Exchanger Data Sheet |

tems, RAS determines precise thermal ratings and mechanical designs for an assortment of shell and tube heat exchangers. Our Q.C. Department is stringent on analyzing every detail during production, all heat exchangers meet the requirements of TEMA and can be designed to the ASME Section VIII Division 1 or Divison 2 Codes. Heat exchangers can be fabricated in all TEMA configurations, from single pass to multi-pass to "U" tube configurations, with or without removable bundles. Heads can be fabricated using traditional bonnets, or with channels to facilitate cleaning the tube side. Impingement protection is available to prevent wear of the tubes on inlet connections. Several types of supports are available such as: saddles for horizontal units and lugs for vertical units.

tems, RAS determines precise thermal ratings and mechanical designs for an assortment of shell and tube heat exchangers. Our Q.C. Department is stringent on analyzing every detail during production, all heat exchangers meet the requirements of TEMA and can be designed to the ASME Section VIII Division 1 or Divison 2 Codes. Heat exchangers can be fabricated in all TEMA configurations, from single pass to multi-pass to "U" tube configurations, with or without removable bundles. Heads can be fabricated using traditional bonnets, or with channels to facilitate cleaning the tube side. Impingement protection is available to prevent wear of the tubes on inlet connections. Several types of supports are available such as: saddles for horizontal units and lugs for vertical units.